When cancer patients undergo chemotherapy, the dose of most drugs is calculated based on the patient’s body surface area. This is estimated by plugging the patient’s height and weight into an equation, dating to 1916, that was formulated from data on just nine patients.

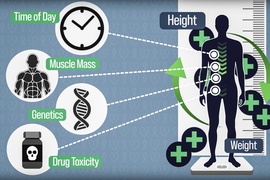

This simplistic dosing doesn’t take into account other factors and can lead to patients receiving either too much or too little of a drug. As a result, some patients likely experience avoidable toxicity or insufficient benefit from the chemotherapy they receive.

To make chemotherapy dosing more accurate, MIT engineers have come up with an alternative approach that can enable the dose to be personalized to the patient. Their system measures how much drug is in the patient’s system, and these measurements are fed into a controller that can adjust the infusion rate accordingly.

This approach could help to compensate for differences in drug pharmacokinetics caused by body composition, genetic makeup, chemotherapy-induced toxicity of the organs that metabolize the drugs, interactions with other medications being taken and foods consumed, and circadian fluctuations in the enzymes responsible for breaking down chemotherapy drugs, the researchers say.

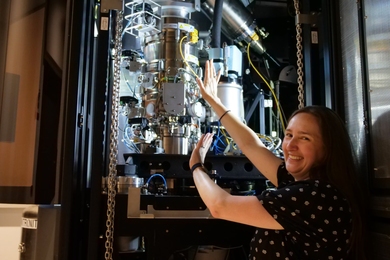

“Recognizing the advances in our understanding of how drugs are metabolized, and applying engineering tools to facilitate personalized dosing, we believe, can help transform the safety and efficacy of many drugs,” says Giovanni Traverso, an associate professor of mechanical engineering at MIT, a gastroenterologist at Brigham and Women’s Hospital, and the senior author of the study.

Louis DeRidder, an MIT graduate student, is the lead author of the paper, which appears today in the journal Med.

Continuous monitoring

In this study, the researchers focused on a drug called 5-fluorouracil, which is used to treat colorectal cancers, among others. The drug is typically infused over a 46-hour period, and the dosage is determined using a formula based on the patient’s height and weight, which gives the estimated body surface area.

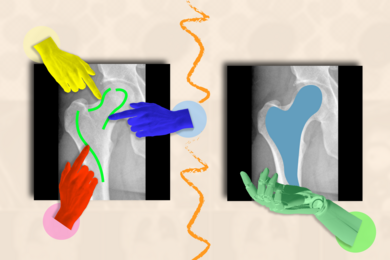

However, that approach doesn’t account for differences in body composition that can affect how the drug spreads through the body, or genetic variations that influence how it is metabolized. Those differences can lead to harmful side effects, if too much drug is present. If not enough drug is circulating, it may not kill the tumor as expected.

“People with the same body surface area could have very different heights and weights, could have very different muscle masses or genetics, but as long as the height and the weight plugged into this equation give the same body surface area, their dose is identical,” says DeRidder, a PhD candidate in the Medical Engineering and Medical Physics program within the Harvard-MIT Program in Health Sciences and Technology.

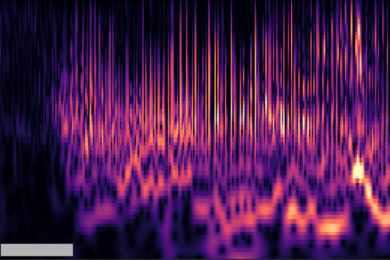

Another factor that can alter the amount of drug in the bloodstream at any given time is circadian fluctuations of an enzyme called dihydropyrimidine dehydrogenase (DPD), which breaks down 5-fluorouracil. DPD’s expression, like many other enzymes in the body, is regulated on a circadian rhythm. Thus, the degradation of 5-FU by DPD is not constant but changes according to the time of the day. These circadian rhythms can lead to tenfold fluctuations in the amount of 5-fluorouracil in a patient’s bloodstream over the course of an infusion.

“Using body surface area to calculate a chemotherapy dose, we know that two people can have profoundly different toxicity from 5-fluorouracil chemotherapy. Looking at one patient, they can have cycles of treatment with minimal toxicity and then have a cycle with miserable toxicity. Something changed in how that patient metabolized chemo from one cycle to the next. Our antiquated dosing fails to capture that change, and patients suffer as a result,” says Douglas Rubinson, a clinical oncologist at Dana-Farber Cancer Institute and an author of the paper.

One way to try to counteract the variability in chemotherapy pharmacokinetics is a strategy called therapeutic drug monitoring, in which the patient gives a blood sample at the end of one treatment cycle. After this sample is analyzed for the drug concentration, the dosage can be adjusted, if needed, at the beginning of the next cycle (usually two weeks later for 5-fluorouracil). This approach has been shown to result in better outcomes for patients, but it is not widely used for chemotherapies such as 5-fluorouracil.

The MIT researchers wanted to develop a similar type of monitoring, but in a manner that is automated and enables real-time drug personalization, which could result in better outcomes for patients. In their “closed-loop” system, drug concentrations can be continually monitored, and that information is used to automatically adjust the infusion rate of the chemotherapy drug and keep the dose within the target range. Such a closed-loop system enables personalization of the drug dose in a manner that considers circadian rhythm changes in the levels of drug-metabolizing enzymes, as well as any changes in the patient’s pharmacokinetics since their last treatment, such as chemotherapy-induced toxicity of the organs that metabolize the drugs.

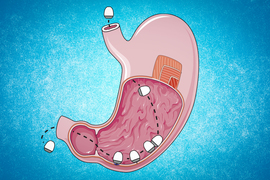

The new system they designed, known as CLAUDIA (Closed-Loop AUtomated Drug Infusion regulAtor), makes use of commercially available equipment for each step. Blood samples are taken every five minutes and rapidly prepared for analysis. The concentration of 5-fluorouracil in the blood is measured and compared to the target range. The difference between the target and measured concentration is input to a control algorithm, which then adjusts the infusion rate if necessary, to keep the dose within the range of concentrations between which the drug is effective and nontoxic.

“What we’ve developed is a system where you can constantly measure the concentration of drug and adjust the infusion rate accordingly, to keep the drug concentration within the therapeutic window,” DeRidder says.

Rapid adjustment

In tests in animals, the researchers found that using CLAUDIA, they could keep the amount of drug circulating in the body within the target range around 45 percent of the time. Drug levels in animals that received chemotherapy without CLAUDIA remained in the target range only 13 percent of the time, on average. In this study, the researchers did not do any tests of the effectiveness of the drug levels, but keeping the concentration within the target window is believed to lead to better outcomes and less toxicity.

CLAUDIA was also able to keep the dose of 5-fluorouracil within the target range even when the researchers administered a drug that inhibits the DPD enzyme. In animals that received this inhibitor without continuous monitoring and adjustment, levels of 5-fluorouracil increased by up to eightfold.

For this demonstration, the researchers manually performed each step of the process, using off-the-shelf equipment, but they now plan to work on automating each step so that the monitoring and dose adjustment can be done without any human intervention.

To measure drug concentrations, the researchers used high-performance liquid chromatography mass spectroscopy (HPLC-MS), a technique that could be adapted to detect nearly any type of drug.

“We foresee a future where we’re able to use CLAUDIA for any drug that has the right pharmacokinetic properties and is detectable with HPLC-MS, thereby enabling the personalization of dosing for many different drugs,” DeRidder says.

The research was funded by the National Science Foundation Graduate Research Fellowship Program, a MathWorks Fellowship, MIT’s Karl van Tassel Career Development Professorship, the MIT Department of Mechanical Engineering, and the Bridge Project, a partnership between the Koch Institute for Integrative Cancer Research at MIT and the Dana-Farber/Harvard Cancer Center.

Other authors of the paper include Kyle A. Hare, Aaron Lopes, Josh Jenkins, Nina Fitzgerald, Emmeline MacPherson, Niora Fabian, Josh Morimoto, Jacqueline N. Chu, Ameya R. Kirtane, Wiam Madani, Keiko Ishida, Johannes L. P. Kuosmanen, Naomi Zecharias, Christopher M. Colangelo, Hen-Wei Huang, Makaya Chilekwa, Nikhil B. Lal, Shriya S. Srinivasan, Alison M Hayward, Brian M. Wolpin, David Trumper, Troy Quast, and Robert Langer.