The radiation detectors used today for applications like inspecting cargo ships for smuggled nuclear materials are expensive and cannot operate in harsh environments, among other disadvantages. Now, in work funded largely by the U.S. Department of Homeland Security with early support from the U.S. Department of Energy, MIT engineers have demonstrated a fundamentally new way to detect radiation that could allow much cheaper detectors and a plethora of new applications.

They are working with Radiation Monitoring Devices, a company in Watertown, Massachusetts, to transfer the research as quickly as possible into detector products.

In a 2022 paper in Nature Materials, many of the same engineers reported for the first time how ultraviolet light can significantly improve the performance of fuel cells and other devices based on the movement of charged atoms, rather than those atoms’ constituent electrons.

In the current work, published recently in Advanced Materials, the team shows that the same concept can be extended to a new application: the detection of gamma rays emitted by the radioactive decay of nuclear materials.

“Our approach involves materials and mechanisms very different than those in presently used detectors, with potentially enormous benefits in terms of reduced cost, ability to operate under harsh conditions, and simplified processing,” says Harry L. Tuller, the R.P. Simmons Professor of Ceramics and Electronic Materials in MIT’s Department of Materials Science and Engineering (DMSE).

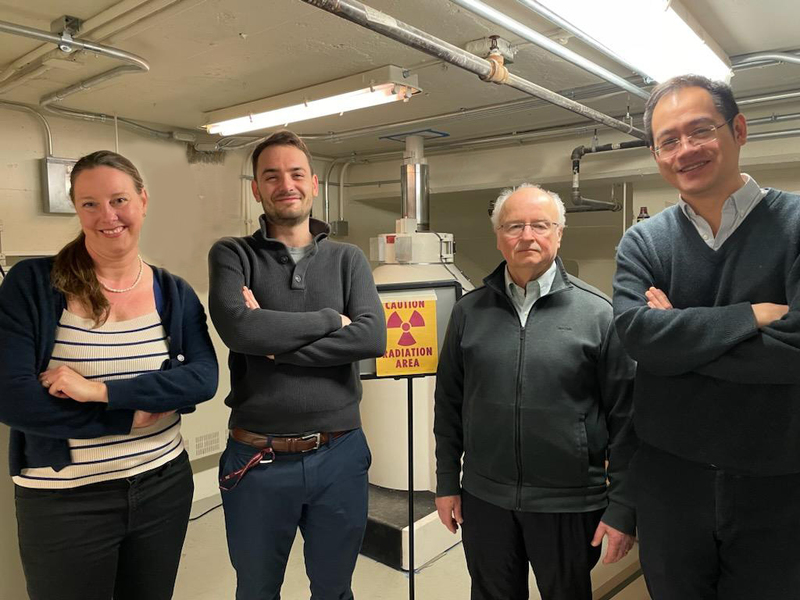

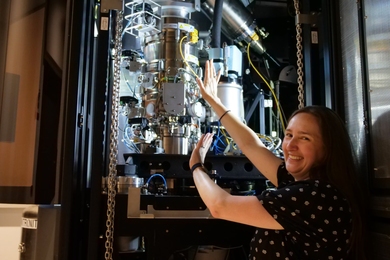

Tuller leads the work with key collaborators Jennifer L. M. Rupp, a former associate professor of materials science and engineering at MIT who is now a professor of electrochemical materials at Technical University Munich in Germany, and Ju Li, the Battelle Energy Alliance Professor in Nuclear Engineering and a professor of materials science and engineering. All are also affiliated with MIT’s Materials Research Laboratory

“After learning the Nature Materials work, I realized the same underlying principle should work for gamma-ray detection — in fact, may work even better than [UV] light because gamma rays are more penetrating — and proposed some experiments to Harry and Jennifer,” says Li.

Says Rupp, “Employing shorter-range gamma rays enable [us] to extend the opto-ionic to a radio-ionic effect by modulating ionic carriers and defects at material interfaces by photogenerated electronic ones.”

Other authors of the Advanced Materials paper are first author Thomas Defferriere, a DMSE postdoc, and Ahmed Sami Helal, a postdoc in MIT’s Department of Nuclear Science and Engineering.

Modifying barriers

Charge can be carried through a material in different ways. We are most familiar with the charge that is carried by the electrons that help make up an atom. Common applications include solar cells. But there are many devices — like fuel cells and lithium batteries — that depend on the motion of the charged atoms, or ions, themselves rather than just their electrons.

The materials behind applications based on the movement of ions, known as solid electrolytes, are ceramics. Ceramics, in turn, are composed of tiny crystallite grains that are compacted and fired at high temperatures to form a dense structure. The problem is that ions traveling through the material are often stymied at the boundaries between the grains.

In their 2022 paper, the MIT team showed that ultraviolet (UV) light shone on a solid electrolyte essentially causes electronic perturbations at the grain boundaries that ultimately lower the barrier that ions encounter at those boundaries. The result: “We were able to enhance the flow of the ions by a factor of three,” says Tuller, making for a much more efficient system.

Vast potential

At the time, the team was excited about the potential of applying what they’d found to different systems. In the 2022 work, the team used UV light, which is quickly absorbed very near the surface of a material. As a result, that specific technique is only effective in thin films of materials. (Fortunately, many applications of solid electrolytes involve thin films.)

Light can be thought of as particles — photons — with different wavelengths and energies. These range from very low-energy radio waves to the very high-energy gamma rays emitted by the radioactive decay of nuclear materials. Visible light — and UV light — are of intermediate energies, and fit between the two extremes.

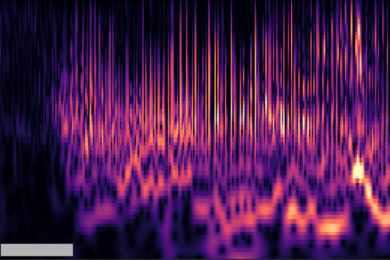

The MIT technique reported in 2022 worked with UV light. Would it work with other wavelengths of light, potentially opening up new applications? Yes, the team found. In the current paper they show that gamma rays also modify the grain boundaries resulting in a faster flow of ions that, in turn, can be easily detected. And because the high-energy gamma rays penetrate much more deeply than UV light, “this extends the work to inexpensive bulk ceramics in addition to thin films,” says Tuller. It also allows a new application: an alternative approach to detecting nuclear materials.

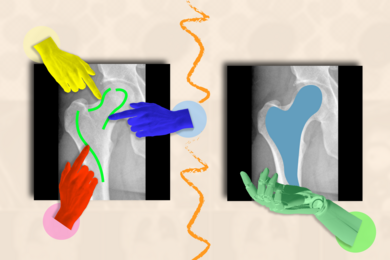

Today’s state-of-the-art radiation detectors depend on a completely different mechanism than the one identified in the MIT work. They rely on signals derived from electrons and their counterparts, holes, rather than ions. But these electronic charge carriers must move comparatively great distances to the electrodes that “capture” them to create a signal. And along the way, they can be easily lost as they, for example, hit imperfections in a material. That’s why today’s detectors are made with extremely pure single crystals of material that allow an unimpeded path. They can be made with only certain materials and are difficult to process, making them expensive and hard to scale into large devices.

Using imperfections

In contrast, the new technique works because of the imperfections — grains — in the material. “The difference is that we rely on ionic currents being modulated at grain boundaries versus the state-of-the-art that relies on collecting electronic carriers from long distances,” Defferriere says.

Says Rupp, “It is remarkable that the bulk ‘grains’ of the ceramic materials tested revealed high stabilities of the chemistry and structure towards gamma rays, and solely the grain boundary regions reacted in charge redistribution of majority and minority carriers and defects.”

Comments Li, “This radiation-ionic effect is distinct from the conventional mechanisms for radiation detection where electrons or photons are collected. Here, the ionic current is being collected.”

Igor Lubomirsky, a professor in the Department of Materials and Interfaces at the Weizmann Institute of Science, Israel, who was not involved in the current work, says, “I found the approach followed by the MIT group in utilizing polycrystalline oxygen ion conductors very fruitful given the [materials’] promise for providing reliable operation under irradiation under the harsh conditions expected in nuclear reactors where such detectors often suffer from fatigue and aging. [They also] benefit from much-reduced fabrication costs.”

As a result, the MIT engineers are hopeful that their work could result in new, less expensive detectors. For example, they envision trucks loaded with cargo from container ships driving through a structure that has detectors on both sides as they leave a port. “Ideally, you’d have either an array of detectors or a very large detector, and that’s where [today’s detectors] really don’t scale very well,” Tuller says.

Another potential application involves accessing geothermal energy, or the extreme heat below our feet that is being explored as a carbon-free alternative to fossil fuels. Ceramic sensors at the ends of drill bits could detect pockets of heat — radiation — to drill toward. Ceramics can easily withstand extreme temperatures of more than 800 degrees Fahrenheit and the extreme pressures found deep below the Earth’s surface.

The team is excited about additional applications for their work. “This was a demonstration of principle with just one material,” says Tuller, “but there are thousands of other materials good at conducting ions.”

Concludes Defferriere: “It’s the start of a journey on the development of the technology, so there’s a lot to do and a lot to discover.”

This work is currently supported by the U.S. Department of Homeland Security, Countering Weapons of Mass Destruction Office. This support does not constitute an express or implied endorsement on the part of the government. It was also funded by the U.S. Defense Threat Reduction Agency.