Farming can be a low-margin, high-risk business, subject to weather and climate patterns, insect population cycles, and other unpredictable factors. Farmers need to be savvy managers of the many resources they deal, and chemical fertilizers and pesticides are among their major recurring expenses.

Despite the importance of these chemicals, a lack of technology that monitors and optimizes sprays has forced farmers to rely on personal experience and rules of thumb to decide how to apply these chemicals. As a result, these chemicals tend to be over-sprayed, leading to their runoff into waterways and buildup up in the soil.

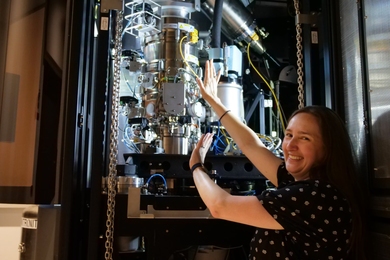

That could change, thanks to a new approach of feedback-optimized spraying, invented by AgZen, an MIT spinout founded in 2020 by Professor Kripa Varanasi and Vishnu Jayaprakash SM ’19, PhD ’22.

Over the past decade, AgZen’s founders have developed products and technologies to control the interactions of droplets and sprays with plant surfaces. The Boston-based venture-backed company launched a new commercial product in 2024 and is currently piloting another related product. Field tests of both have shown the products can help farmers spray more efficiently and effectively, using fewer chemicals overall.

“Worldwide, farms spend approximately $60 billion a year on pesticides. Our objective is to reduce the number of pesticides sprayed and lighten the financial burden on farms without sacrificing effective pest management,” Varanasi says.

Getting droplets to stick

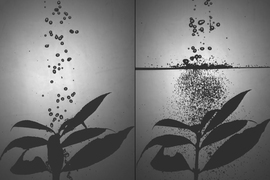

While the world pesticide market is growing rapidly, a lot of the pesticides sprayed don’t reach their target. A significant portion bounces off the plant surfaces, lands on the ground, and becomes part of the runoff that flows to streams and rivers, often causing serious pollution. Some of these pesticides can be carried away by wind over very long distances.

“Drift, runoff, and poor application efficiency are well-known, longstanding problems in agriculture, but we can fix this by controlling and monitoring how sprayed droplets interact with leaves,” Varanasi says.

With support from MIT Tata Center and the Abdul Latif Jameel Water and Food Systems Lab, Varanasi and his team analyzed how droplets strike plant surfaces, and explored ways to increase application efficiency. This research led them to develop a novel system of nozzles that cloak droplets with compounds that enhance the retention of droplets on the leaves, a product they call EnhanceCoverage.

Field studies across regions — from Massachusetts to California to Italy and France —showed that this droplet-optimization system could allow farmers to cut the amount of chemicals needed by more than half because more of the sprayed substances would stick to the leaves.

Measuring coverage

However, in trying to bring this technology to market, the researchers faced a sticky problem: Nobody knew how well pesticide sprays were adhering to the plants in the first place, so how could AgZen say that the coverage was better with its new EnhanceCoverage system?

“I had grown up spraying with a backpack on a small farm in India, so I knew this was an issue,” Jayaprakash says. “When we spoke to growers, they told me how complicated spraying is when you’re on a large machine. Whenever you spray, there are so many things that can influence how effective your spray is. How fast do you drive the sprayer? What flow rate are you using for the chemicals? What chemical are you using? What’s the age of the plants, what’s the nozzle you’re using, what is the weather at the time? All these things influence agrochemical efficiency.”

Agricultural spraying essentially comes down to dissolving a chemical in water and then spraying droplets onto the plants. “But the interaction between a droplet and the leaf is complex,” Varanasi says. “We were coming in with ways to optimize that, but what the growers told us is, hey, we’ve never even really looked at that in the first place.”

Although farmers have been spraying agricultural chemicals on a large scale for about 80 years, they’ve “been forced to rely on general rules of thumb and pick all these interlinked parameters, based on what’s worked for them in the past. You pick a set of these parameters, you go spray, and you’re basically praying for outcomes in terms of how effective your pest control is,” Varanasi says.

Before AgZen could sell farmers on the new system to improve droplet coverage, the company had to invent a way to measure precisely how much spray was adhering to plants in real-time.

Comparing before and after

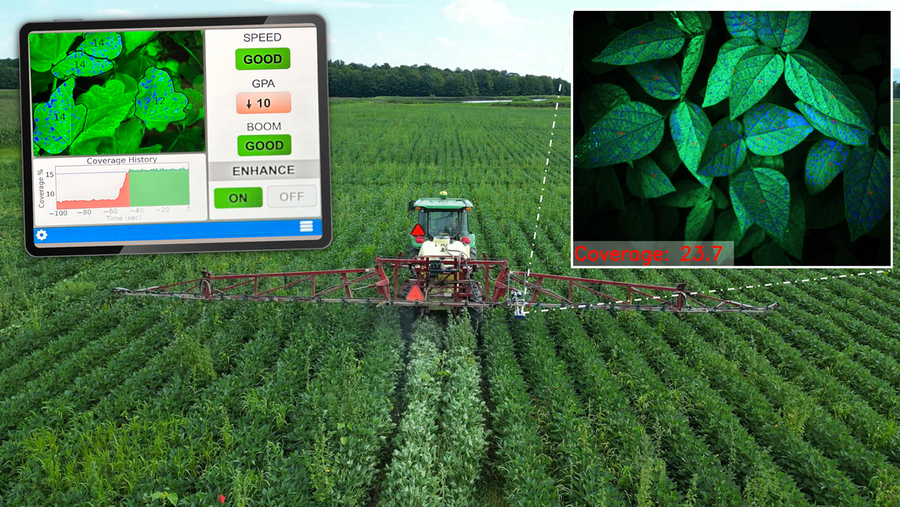

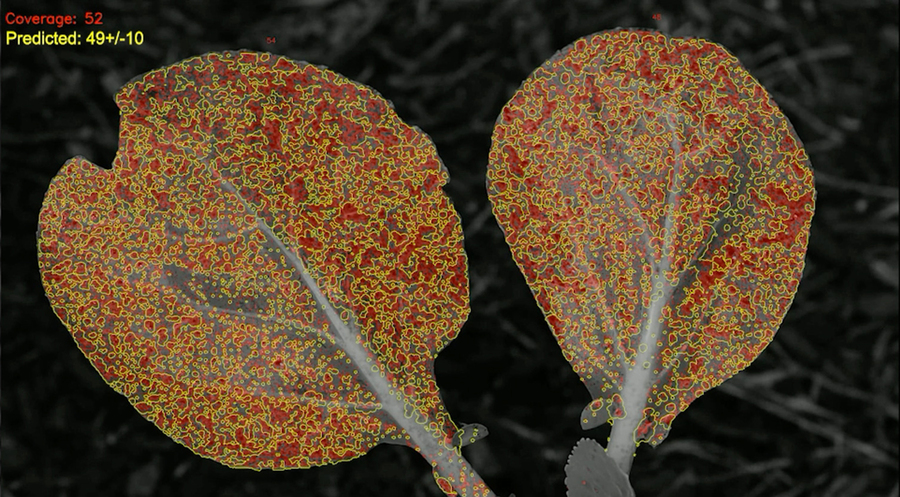

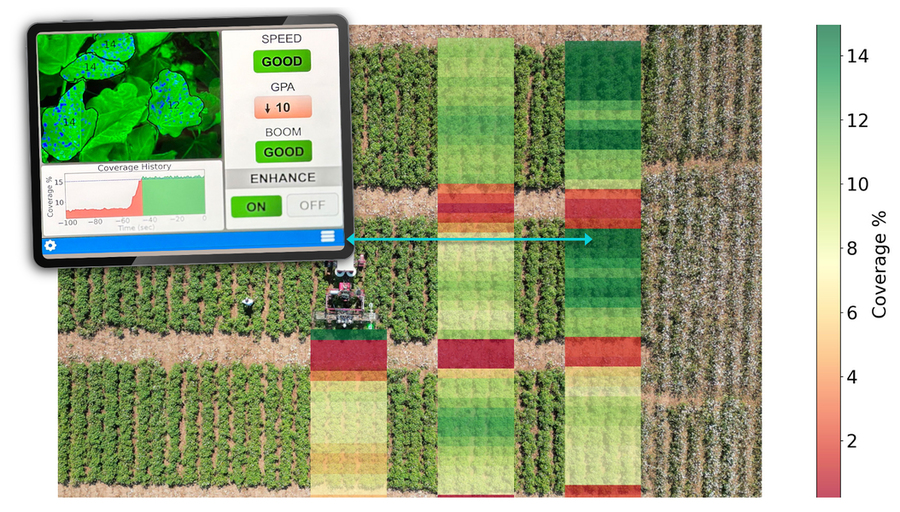

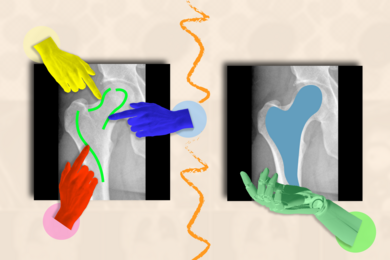

The system they came up with, which they tested extensively on farms across the country last year, involves a unit that can be bolted onto the spraying arm of virtually any sprayer. It carries two sensor stacks, one just ahead of the sprayer nozzles and one behind. Then, built-in software running on a tablet shows the operator exactly how much of each leaf has been covered by the spray. It also computes how much those droplets will spread out or evaporate, leading to a precise estimate of the final coverage.

“There’s a lot of physics that governs how droplets spread and evaporate, and this has been incorporated into software that a farmer can use,” Varanasi says. “We bring a lot of our expertise into understanding droplets on leaves. All these factors, like how temperature and humidity influence coverage, have always been nebulous in the spraying world. But now you have something that can be exact in determining how well your sprays are doing.”

“We’re not only measuring coverage, but then we recommend how to act,” says Jayaprakash, who is AgZen’s CEO. “With the information we collect in real-time and by using AI, RealCoverage tells operators how to optimize everything on their sprayer, from which nozzle to use, to how fast to drive, to how many gallons of spray is best for a particular chemical mix on a particular acre of a crop.”

The tool was developed to prove how much AgZen’s EnhanceCoverage nozzle system (which will be launched in 2025) improves coverage. But it turns out that monitoring and optimizing droplet coverage on leaves in real-time with this system can itself yield major improvements.

“We worked with large commercial farms last year in specialty and row crops,” Jayaprakash says. “When we saved our pilot customers up to 50 percent of their chemical cost at a large scale, they were very surprised.” He says the tool has reduced chemical costs and volume in fallow field burndowns, weed control in soybeans, defoliation in cotton, and fungicide and insecticide sprays in vegetables and fruits. Along with data from commercial farms, field trials conducted by three leading agricultural universities have also validated these results.

“Across the board, we were able to save between 30 and 50 percent on chemical costs and increase crop yields by enabling better pest control,” Jayaprakash says. “By focusing on the droplet-leaf interface, our product can help any foliage spray throughout the year, whereas most technological advancements in this space recently have been focused on reducing herbicide use alone.” The company now intends to lease the system across thousands of acres this year.

And these efficiency gains can lead to significant returns at scale, he emphasizes: In the U.S., farmers currently spend $16 billion a year on chemicals, to protect about $200 billion of crop yields.

The company launched its first product, the coverage optimization system called RealCoverage, this year, reaching a wide variety of farms with different crops and in different climates. “We’re going from proof-of-concept with pilots in large farms to a truly massive scale on a commercial basis with our lease-to-own program,” Jayaprakash says.

“We’ve also been tapped by the USDA to help them evaluate practices to minimize pesticides in watersheds,” Varanasi says, noting that RealCoverage can also be useful for regulators, chemical companies, and agricultural equipment manufacturers.

Once AgZen has proven the effectiveness of using coverage as a decision metric, and after the RealCoverage optimization system is widely in practice, the company will next roll out its second product, EnhanceCoverage, designed to maximize droplet adhesion. Because that system will require replacing all the nozzles on a sprayer, the researchers are doing pilots this year but will wait for a full rollout in 2025, after farmers have gained experience and confidence with their initial product.

“There is so much wastage,” Varanasi says. “Yet farmers must spray to protect crops, and there is a lot of environmental impact from this. So, after all this work over the years, learning about how droplets stick to surfaces and so on, now the culmination of it in all these products for me is amazing, to see all this come alive, to see that we’ll finally be able to solve the problem we set out to solve and help farmers.”