“It’s all about the process,” says MIT professor Warren Seering.

He’s referring to his spring design class, Course 2.739 (Product Design and Development) — but he could easily be talking about product development itself.

“We want 2.739 students to leave with a set of methods readily available to them to use at whatever stage they are at in the development process,” says Seering, a professor of mechanical engineering. “This is their introduction to a much more structured approach to developing new products.”

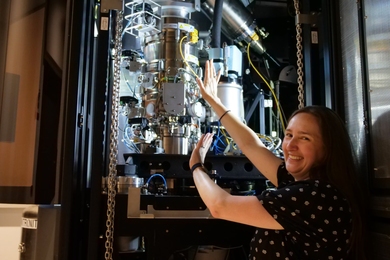

The students of Course 2.739 experience that structure first-hand as they design and develop a new product throughout the semester on a team of six to eight members. Each team consists of at least one engineering student, one MIT Sloan School of Management student, and one student from the Rhode Island School of Design (RISD), which partners with MIT for the course.

The benefit of bringing together students from different backgrounds — engineering, business, and industrial design — represents the students’ first real-world lesson, Seering says: learning how to value and collaborate with contributors from various disciplines as they develop a successful product together.

“At this past spring’s final presentation of products, I played a game with one of the reviewers to see if they could guess which school each student was from — School of Engineering, [MIT] Sloan School of Management, or RISD,” Seering says. “It was difficult for them. By the end, it’s not so easy to tell the difference. And that’s what we want. It means that the students have really learned from each other.”

Course 2.739 brings these three groups of students together twice a week at MIT for lectures from both MIT and RISD professors (Sloan Professor Steven Eppinger and RISD Professor Matt Kressy co-teach the class with Seering), followed by a hands-on lab. Lab time focuses on the main project of the course: developing a new product, a process that must include consumer research, design, prototyping, financials, marketing, testing, and a final presentation of the manufactured prototype.

“The mechanical engineers work out feasibility and production methods, but we also want them to learn how to do the parts that the other team members do too,” Seering says. “We want them to be able to interact with those types of people in an enlightened way. Because it’s a big group, they have to help one another or they won’t get it done.”

“Working with a team from diverse and unique backgrounds was an amazing experience,” says student Stephanie Scott, who took the course in spring 2013. “Occasionally team members disagreed on approach. Students with different backgrounds tended to prioritize different parts of the product. We worked together to explore tradeoffs of different approaches, and that process ultimately led to the development of a more successful product.”

The final presentations take place at RISD and MIT in alternating years and are presented in front of an audience, as well as a board of reviewers. The students are judged on the market value of their product idea, their justification for the market opportunity, the quality of the prototype, and the effectiveness of their presentation. Before the presentation, groups often patent their products; some of them even pursue manufacturing and sales once the course has ended.

This past May, the final presentations held at RISD revealed products that solved real consumer problems. One team, AvaTech, solved the problem of predicting avalanches for mountain climbers. The team (Allie Owens, Jim Christian, Sam Whittemore, Tom Sanderson, Paul Meggs, Tais Mauk, Hugo Ni, and Brint Markle) developed a fold-out sensor that can be stuck into the snow at meaningful depths to analyze and report on the amount of soft snow versus ice at specific layers. They recently started a company based on their innovation.

Another team addressed the demoralization sick children in hospitals feel when they have to wear face masks. The group (Stephen Frechette, Michael Joyce, Jeff Mekler, Stephanie Scott, Ryan Surveski, Denise Thornberry, Chris Wilson, and Tianyu Zhu) developed Fantastic Faces, which is a mask-decorating kit that aims to add an element of fun to an otherwise disheartening experience. They also spun out a company.

A third team, Steam-Ez (Ash Koul, Elina Hu, Emily Albert, Josh Przybylko, Lana Cohen, Lauren Lo, Paulina Mustafa, and Wooho Park), developed an all-in-one product for cleaning the hard-to-eliminate food mess from the inside of microwaves. The product is a specially designed sponge that comes with an all-natural solid solution that turns to steam when placed in the microwave for three minutes. The steamed formula attaches to the dirt and food in the microwave, making it easier to wipe up with the sponge.

“Even with 10 years of industry experience in manufacturing, I didn’t have product design on my radar at all prior to taking this class,” says David McCalib MEng ’13, who just started his new position as design engineer at Amazon. “But now I’m always thinking about it and have more tools than I ever did before. It was like training wheels for product development. Now we have the confidence to do it ourselves.”

He’s referring to his spring design class, Course 2.739 (Product Design and Development) — but he could easily be talking about product development itself.

“We want 2.739 students to leave with a set of methods readily available to them to use at whatever stage they are at in the development process,” says Seering, a professor of mechanical engineering. “This is their introduction to a much more structured approach to developing new products.”

The students of Course 2.739 experience that structure first-hand as they design and develop a new product throughout the semester on a team of six to eight members. Each team consists of at least one engineering student, one MIT Sloan School of Management student, and one student from the Rhode Island School of Design (RISD), which partners with MIT for the course.

The benefit of bringing together students from different backgrounds — engineering, business, and industrial design — represents the students’ first real-world lesson, Seering says: learning how to value and collaborate with contributors from various disciplines as they develop a successful product together.

“At this past spring’s final presentation of products, I played a game with one of the reviewers to see if they could guess which school each student was from — School of Engineering, [MIT] Sloan School of Management, or RISD,” Seering says. “It was difficult for them. By the end, it’s not so easy to tell the difference. And that’s what we want. It means that the students have really learned from each other.”

Course 2.739 brings these three groups of students together twice a week at MIT for lectures from both MIT and RISD professors (Sloan Professor Steven Eppinger and RISD Professor Matt Kressy co-teach the class with Seering), followed by a hands-on lab. Lab time focuses on the main project of the course: developing a new product, a process that must include consumer research, design, prototyping, financials, marketing, testing, and a final presentation of the manufactured prototype.

“The mechanical engineers work out feasibility and production methods, but we also want them to learn how to do the parts that the other team members do too,” Seering says. “We want them to be able to interact with those types of people in an enlightened way. Because it’s a big group, they have to help one another or they won’t get it done.”

“Working with a team from diverse and unique backgrounds was an amazing experience,” says student Stephanie Scott, who took the course in spring 2013. “Occasionally team members disagreed on approach. Students with different backgrounds tended to prioritize different parts of the product. We worked together to explore tradeoffs of different approaches, and that process ultimately led to the development of a more successful product.”

The final presentations take place at RISD and MIT in alternating years and are presented in front of an audience, as well as a board of reviewers. The students are judged on the market value of their product idea, their justification for the market opportunity, the quality of the prototype, and the effectiveness of their presentation. Before the presentation, groups often patent their products; some of them even pursue manufacturing and sales once the course has ended.

This past May, the final presentations held at RISD revealed products that solved real consumer problems. One team, AvaTech, solved the problem of predicting avalanches for mountain climbers. The team (Allie Owens, Jim Christian, Sam Whittemore, Tom Sanderson, Paul Meggs, Tais Mauk, Hugo Ni, and Brint Markle) developed a fold-out sensor that can be stuck into the snow at meaningful depths to analyze and report on the amount of soft snow versus ice at specific layers. They recently started a company based on their innovation.

Another team addressed the demoralization sick children in hospitals feel when they have to wear face masks. The group (Stephen Frechette, Michael Joyce, Jeff Mekler, Stephanie Scott, Ryan Surveski, Denise Thornberry, Chris Wilson, and Tianyu Zhu) developed Fantastic Faces, which is a mask-decorating kit that aims to add an element of fun to an otherwise disheartening experience. They also spun out a company.

A third team, Steam-Ez (Ash Koul, Elina Hu, Emily Albert, Josh Przybylko, Lana Cohen, Lauren Lo, Paulina Mustafa, and Wooho Park), developed an all-in-one product for cleaning the hard-to-eliminate food mess from the inside of microwaves. The product is a specially designed sponge that comes with an all-natural solid solution that turns to steam when placed in the microwave for three minutes. The steamed formula attaches to the dirt and food in the microwave, making it easier to wipe up with the sponge.

“Even with 10 years of industry experience in manufacturing, I didn’t have product design on my radar at all prior to taking this class,” says David McCalib MEng ’13, who just started his new position as design engineer at Amazon. “But now I’m always thinking about it and have more tools than I ever did before. It was like training wheels for product development. Now we have the confidence to do it ourselves.”